Safety bench Class 1 – Scanlaf Jupiter

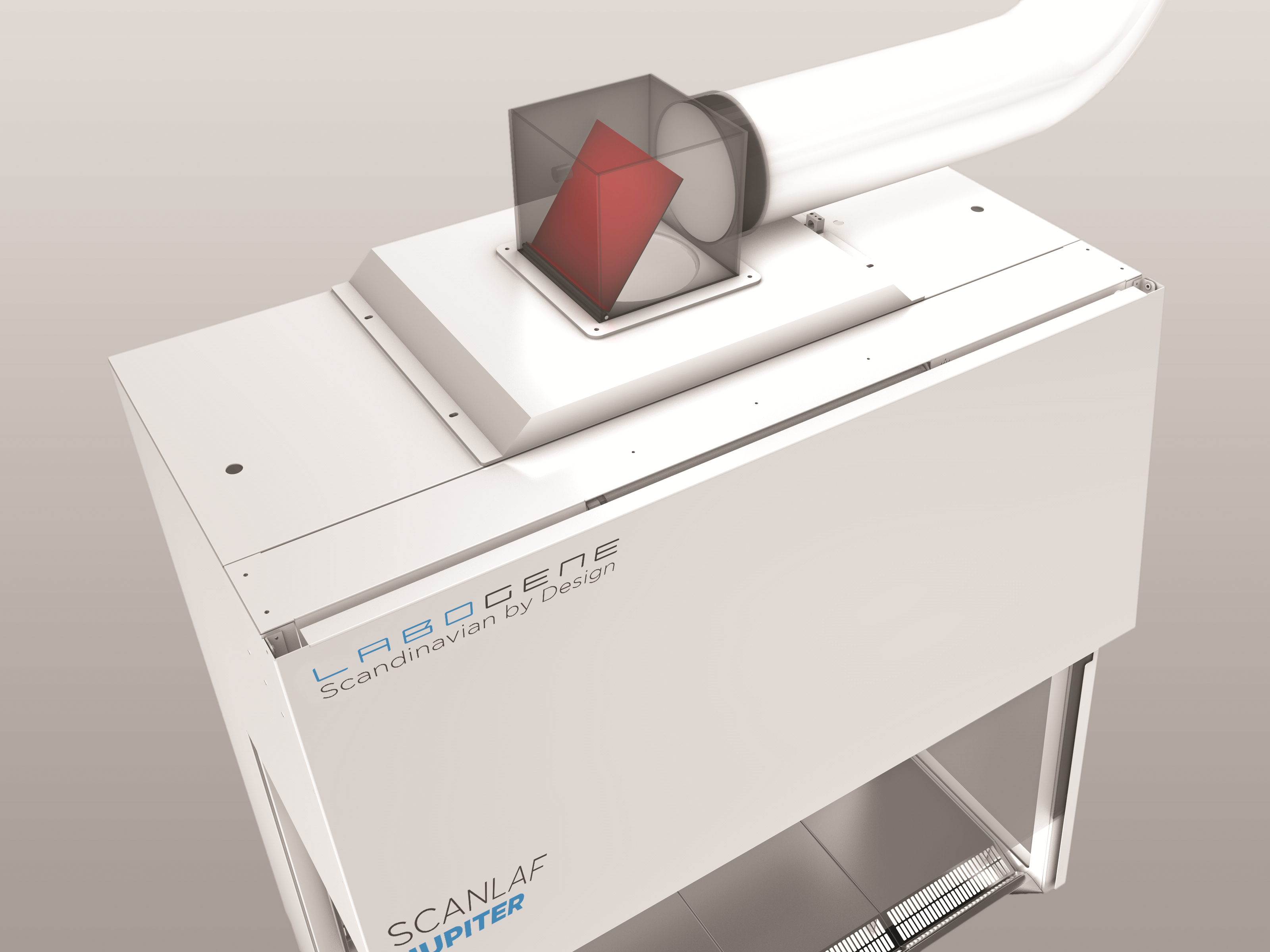

Jupiter Class I biosafety bench offers user and environmental protection where the air is drawn from the laboratory space into the work opening and then out to the room or ventilation system. The extract air is filtered through a HEPA filter.

The Jupiter safety bench is suitable for working with the extraction of large amounts of organic compounds, airborne particles, powder materials and salts.

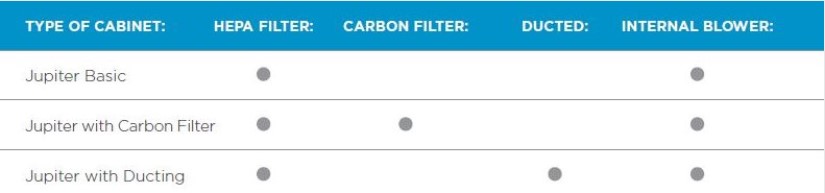

Jupiter Class I is a series of vertical flow safety bench containing the latest technology and energy-saving designs. The Jupiter series is available in different models and alternatives, which provides optimum performance and protection for both the user and the environment.

Class I or Class II?

The cabinet is not suitable for handling research materials that are vulnerable to airborne pollution, as the inflow of unfiltered air from the laboratory can cause contamination inside the cabinet. In these cases, safety cabinets are class II preferred!

How does it work?

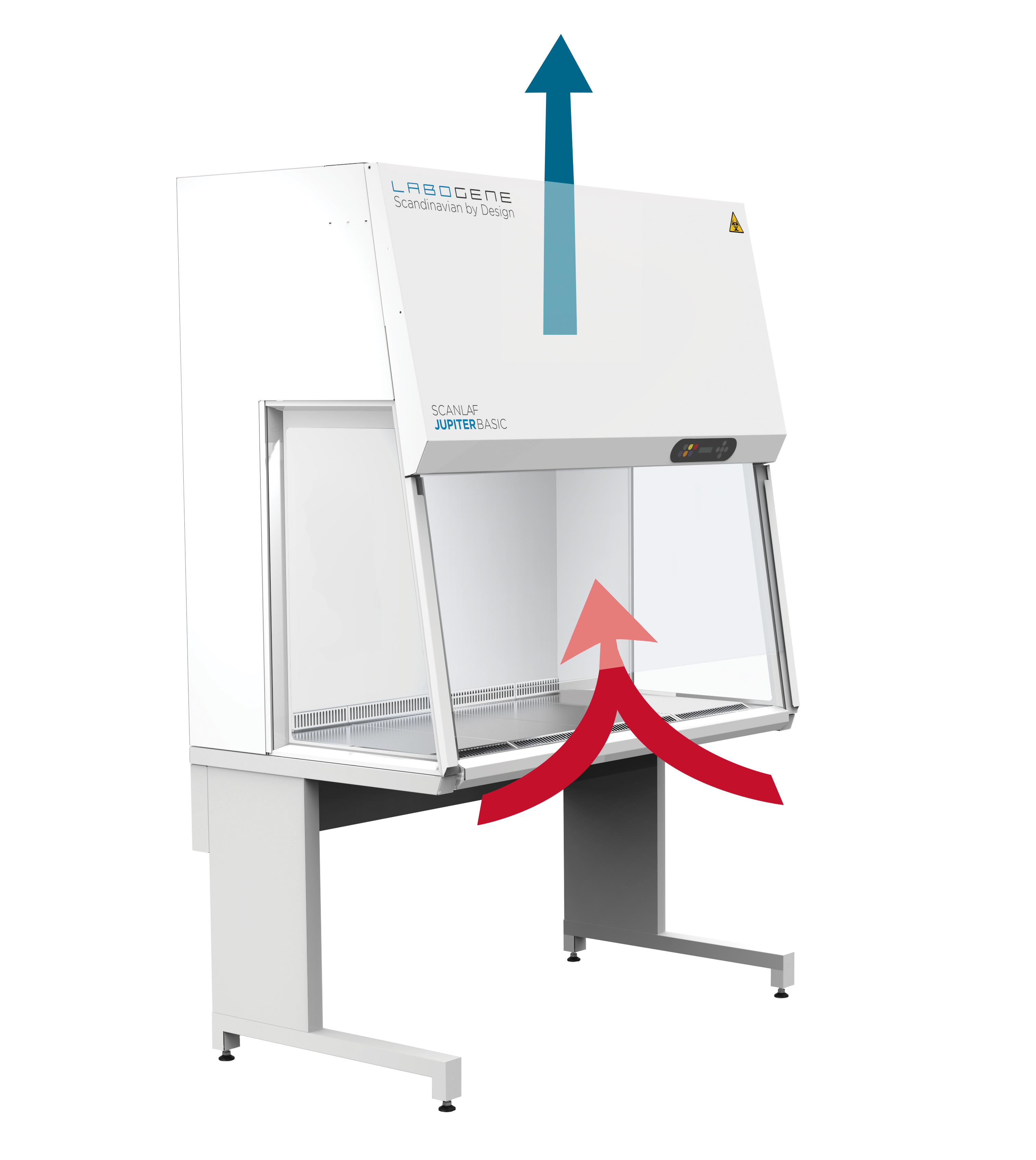

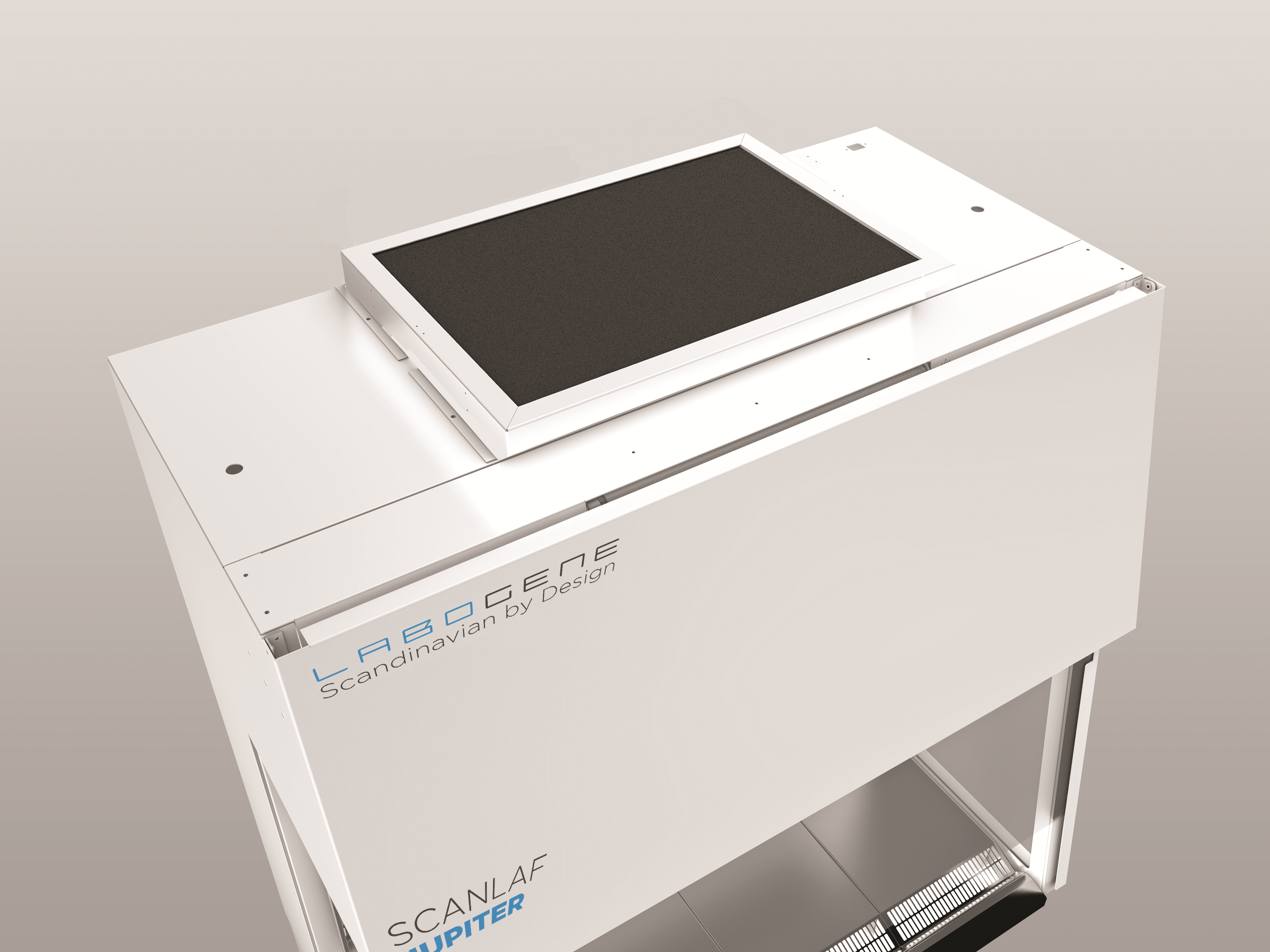

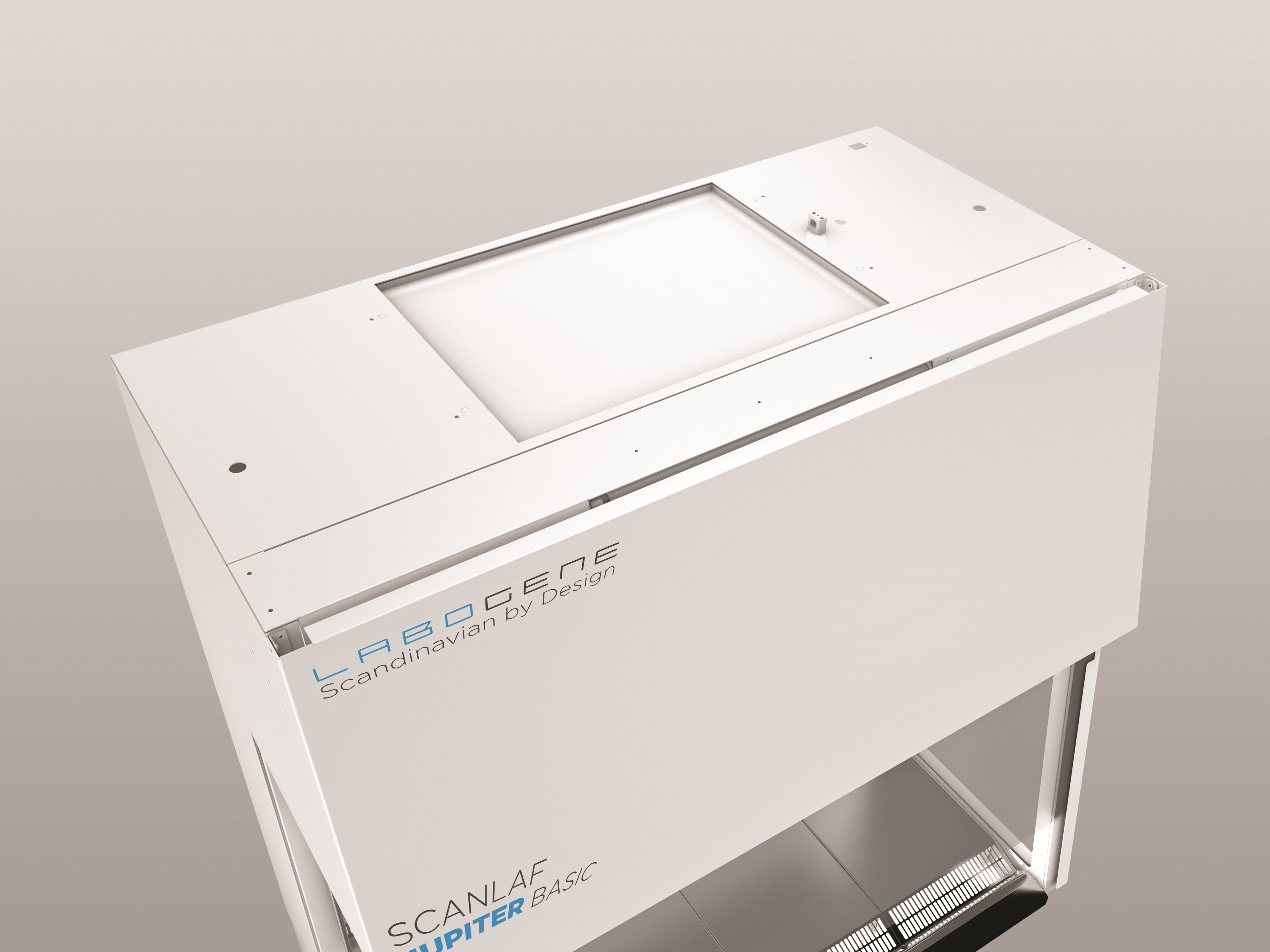

The air enters the cabinet via the front opening which passes through a built-in exhaust air fan, HEPA and / or carbon filter, which provides personal and environmental protection. The air then comes out of the cabinet on the back of the work surface. Disposal of airborne particles generated in the cabinet is therefore controlled by means of the internal air flow through the front opening and by filtration / absorption of the exhaust air. Unlike conventional fume cupboards, the HEPA filter in the cabinet protects the environment by filtering the air before blowing it out.

Sizes are available in four different working widths: 900 mm, 1200 mm, 1500 mm and 1800 mm.